The FDA published on December 5th the final issue of the guidance document “Technical Considerations for Additive Manufactured Medical Devices“, dedicated to manufacturers intending to exploit this new process.

This 31 pages document details the current thinking of the FDA regarding additive manufacturing (AM). It is not a standard or a regulation, but a list of advices that manufacturers may chose to follow in order to facilitate the approval of additive manufactured medical devices.

The main topics to consider are as follow:

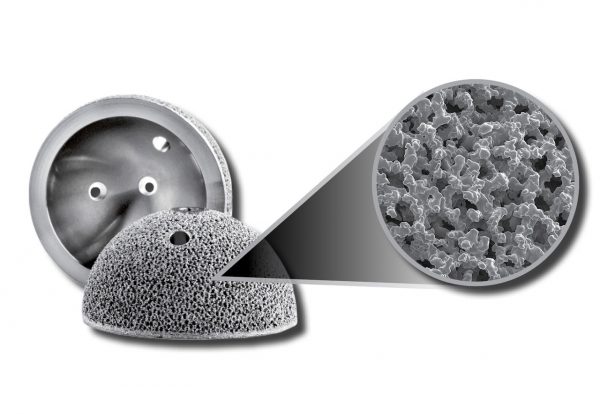

- Device design: interesting design innovations are allowed with AM, however care must be taken because of technological limitations (low printing resolution, surfaces pixelisation …) that may necessitate finishing operations.

- Software workflow: AM involves more software processing than conventional manufacturing process, so the manufacturer should make sure that the integrity of data is preserved while they are converted by the different software applications. The FDA advise the use of the standard AMF format (Additive Manufacturing File).

- Raw material management: material characterisation, material reuse …

- Post-processing operations: such as finishing, heat treatment or HIP (Hot Isostatic Pressing).

- Process validation: an IQ OQ PQ qualification is advised, and acceptance criteria are suggested.

- Quality data to consider: data that should be recorded, for instance.

- Device testing consideration: dimensional, mechanical, material …

- Removing manufacturing material residues and sterilization: as the porosity and surface area of additive manufactured device may be greatly inscreased, they are more difficult to clean.

- Biocompatibility: with no surprise, it is advised to follow the requirement of ISO 10993-1.

- Labeling: no particular requirements.

This guide will prove useful to manufacturers that are considering using additive processes for medical device manufacturing. From there, an action plan can be drawn and a project schedule defined.

There is currently no European equivalent, and a few notified body are a bit reluctant when asked to evaluate an implant manufactured with an additive process. Like the FDA, European authorities would gain in quickly explaining there position regarding additive manufacturing, in order to incitate (or not) manufacturers to exploit this promising technology.